Firearms. Use Electrochemical – EC Rifling by Extrude Hone.

Leave nothing to chance, use Electrochemical – EC Rifling for state-of-the-art rifling, improved productivity, and outstanding quality.

For decades, we are doing EC-rifling in our USA contract shop.

Today a new 3D animation explains EC-rifling, Static and Dynamic. It’s available at Extrude Hone Virtual booth.

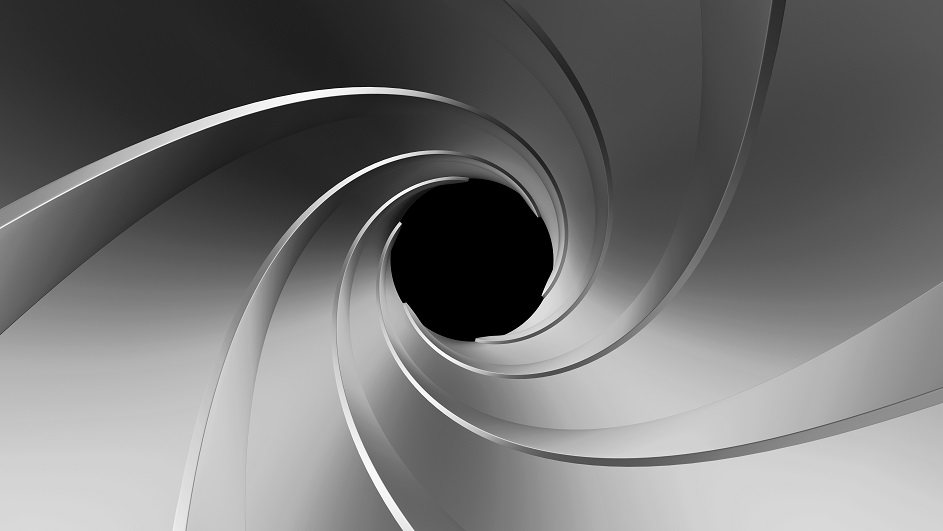

Rifling helps impart a spinning motion to the bullet when it’s fired. Rifling applies to Rifle and Handgun.

Mechanical rifling is a far from a perfect process.

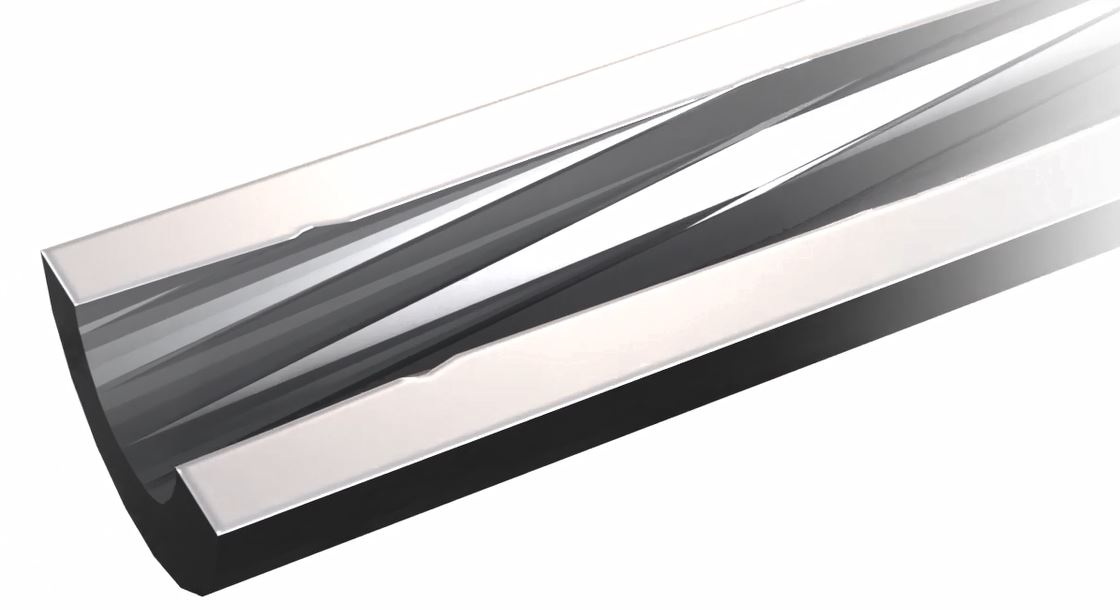

The incoming bore condition if reamed average Ra 0.4µm (16µin). The length of the barrel will determine the possible EC rifling solution, either Static or Dynamic.

A very high-precision twisted cathode is designed and machined. Static cathodes can be up to 160mm long while the shortest mobile cathode section is used for EC Dynamic long barrel applications.

The cathode will generate the final design inside the barrel during the Electrochemical machining process.

It takes about 23 seconds for a handgun barrel to be machined.

Look at our 3D animation EC- rifling at Extrude Hone Virtual Booth under “General Engineering”, “Application Corner “, and “Video gallery”.

The very best barrel rifling for greater precision. Leave nothing to chance. Use Electrochemical – EC Rifling by Extrude Hone.

The Science Behind

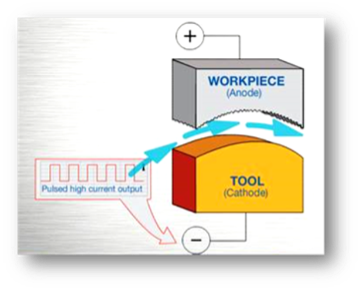

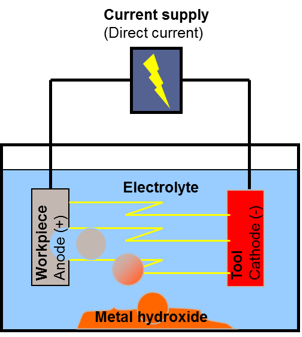

EC rifling leverages the dissolutions of the material and is governed by Faraday’s law of electrolysis.

The mass of a metal dissolved is proportional to the quantity of electrical charges transferred to the electrode.