EXTRUDE HONE TECHNOLOGY IMPROVES EQUIPMENT FOR DIALYSIS PATIENTS.

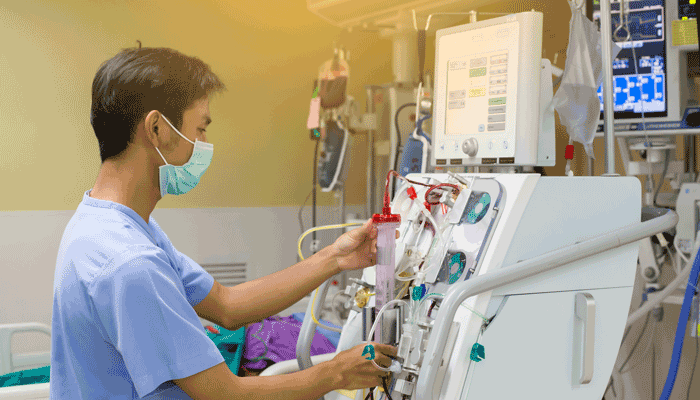

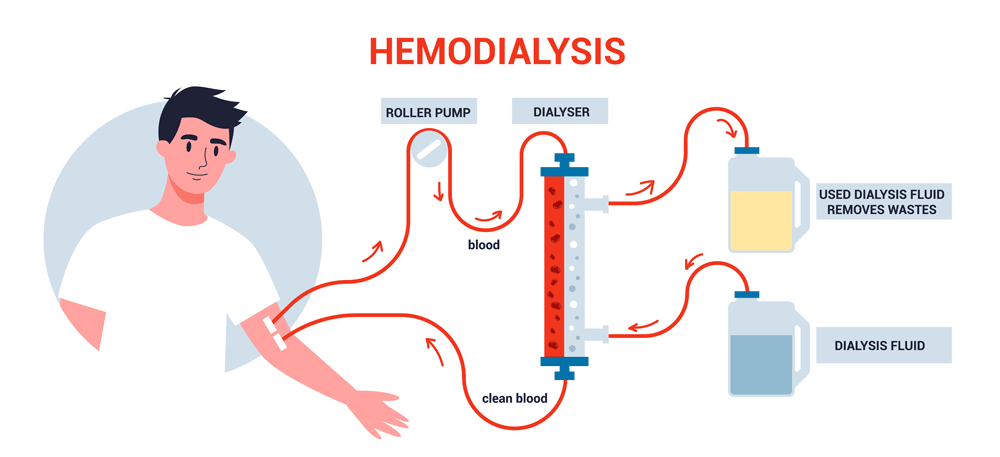

10% of the population is affected by chronic kidney disease. There are two treatments for kidney failure: transplant and dialysis. 2M+ patient worldwide receive dialysis treatment. Discover how Extrude Hone contribute to help dialyzer manufacturers.

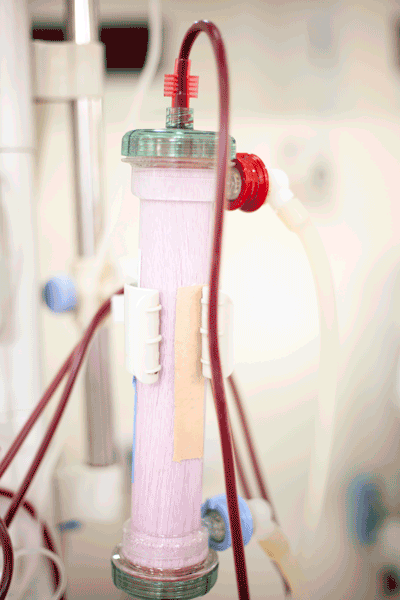

Different filters are used in dialysis equipment which means dialysis machines, dialyzer and hemofilter may have different membranes, housings and headers.

For one global leading manufacturer, one challenge they faced was related to the manufacturing of multiple colored headers. The problem was related to the hot runners’ internal passages used in the polypropylene or polycarbonate injection process used to manufacture the housings and headers. Part of the challenge also related to the fact that the headers are either blue, red or transparent necessitating the need to switch colors frequently on the injection molding machines.

Typically, maintenance of injection molding hot runners manually has not been possible. When changing colors, it is often necessary to perform wasted resin shots and sometimes the resin may get burnt in the internal passages of the hot runner resulting in additional cost to set up additional machine capacity. However, after the introduction of the AFM processing machine, regular maintenance of the hot runners is fast and automatic significantly increasing the production productivity and reducing costs.

By maintaining the hot runner manifold, it is possible to prevent the resin from burning.

There can be no foreign matter in the medical field. For example, if black spots appear on a transparent product, the manufacturer must recall it. Surprisingly, it costs about 200 million yen ($200.000) a year to recall product for foreign matter. However, by performing mold maintenance with AFM the recall will be eliminated.

By controlling the abrasives and processing pressure and processing time, it is the only technology that can significantly improve the accuracy and application of manifolds for the medical, food and precision fields.

Learn more about AFM Technology: https://pl.extrudehone.com/products/abrasive-flow-machining-afm/