Offer your equipment a second life by thinking refurbishment!

There are three main reasons to consider going for an equipment refurbishment: saving resources, spending less and reducing lead time.

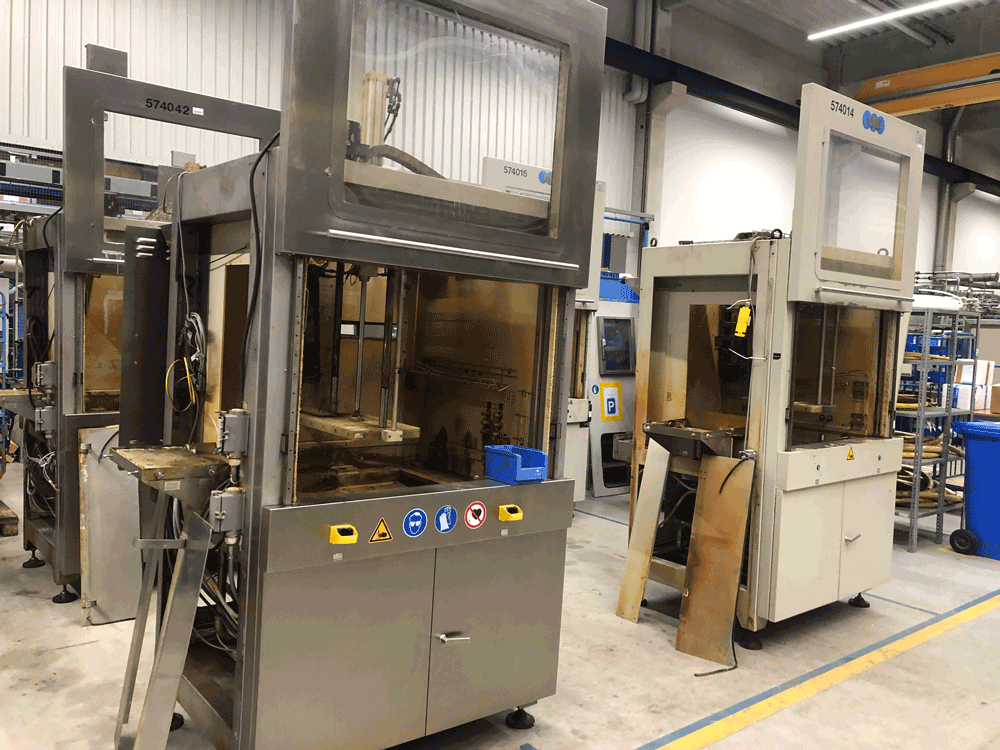

Your current equipment is aging, it’s years since you have installed that machine. It has served you well during times of intense production, being flexible to your needs beyond expectation. However, the machine may now feel to you past its best?

Maintenance costs are skyrocketing, and some electronic components will soon be obsolete.

You are thinking of buying a new machine; great idea!

Unfortunately, a few things possibly went wrong: inflation has dwarfed your budget, up to one year lead time makes you desperate, and you feel guilty when you look at the base machine that is still in good shape.

Do yourself a favor, and think about refurbishment.

The refurbishment is an opportunity to revamp your equipment by:

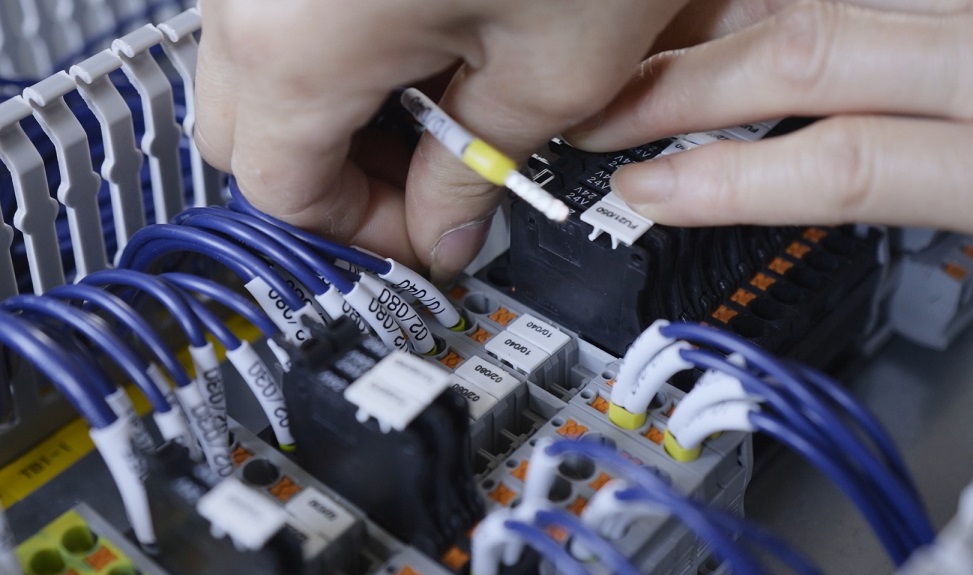

– replacing obsolete electronic components.

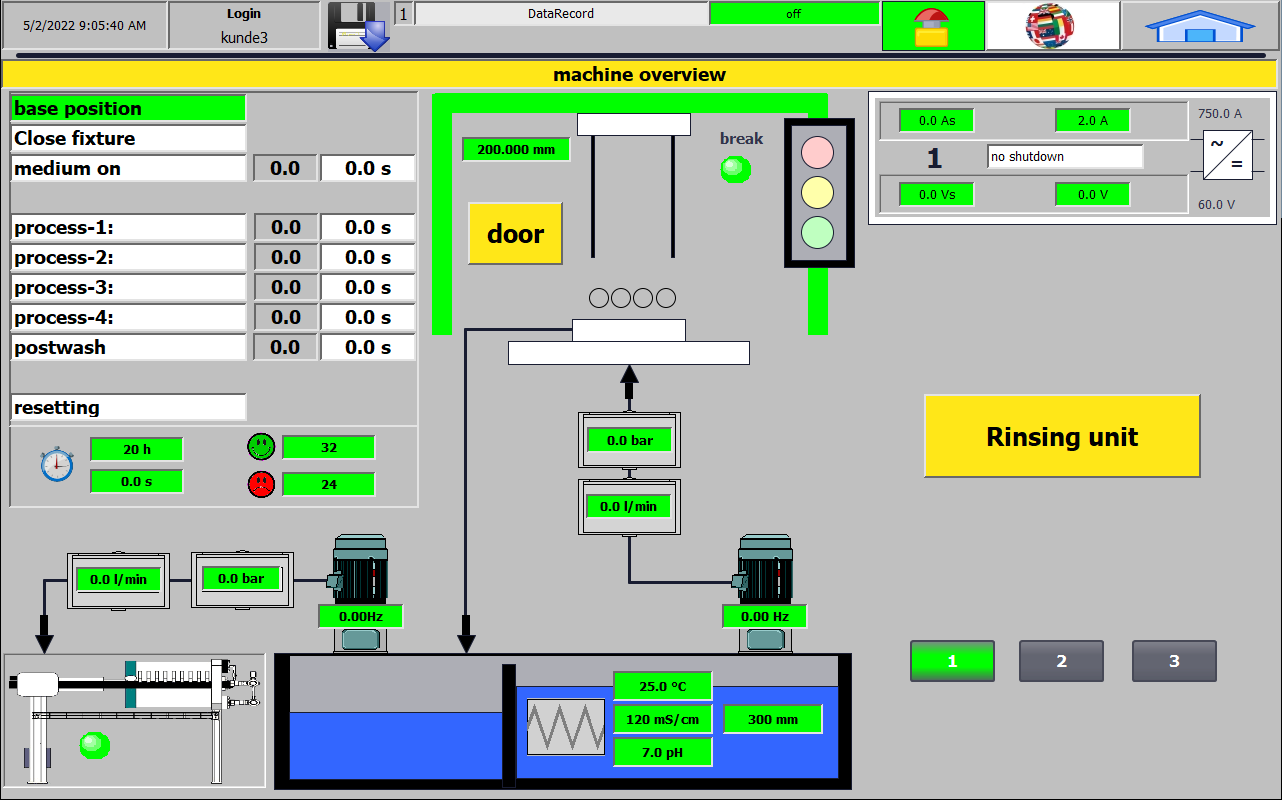

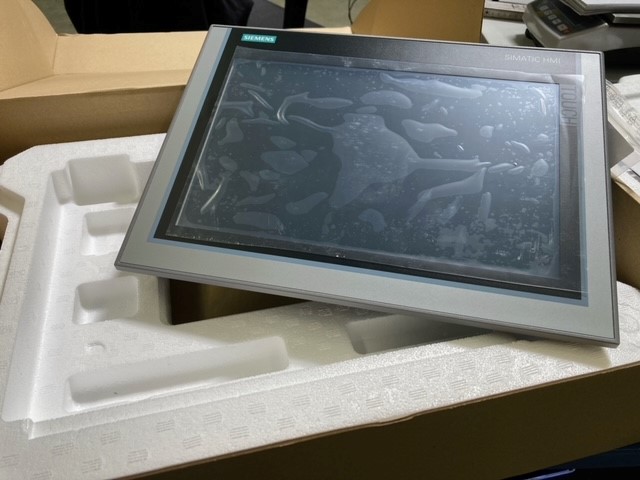

– bringing a state-of-the-art control and HMI while unlocking program capabilities

– modernizing fixture handling by bringing new interface features that contribute to productivity gain while making handling easy and safer.

– replacing hidden wear parts that have aged will get you back to lower maintenance and service cost.

– adding a Preventive Maintenance Program will make ownership of the machine a breeze.

Of course, machine capacity in terms of working space and the max part dimension your machine can accommodate won’t change.

Nevertheless, a new clever tooling arrangement combined with new control abilities could boost capabilities and enhance productivity.

Control abilities being improved means your equipment will better manage the process and deliver better end-product quality.

The good news is it can be done for a fraction of the cost of new equipment.

Another benefit is that refurbishment takes much less time than the delivery of new equipment.

Capability-wise you should be close to what latest state of the art equipment offers and you could promote being greener as having done the right thing for the planet.

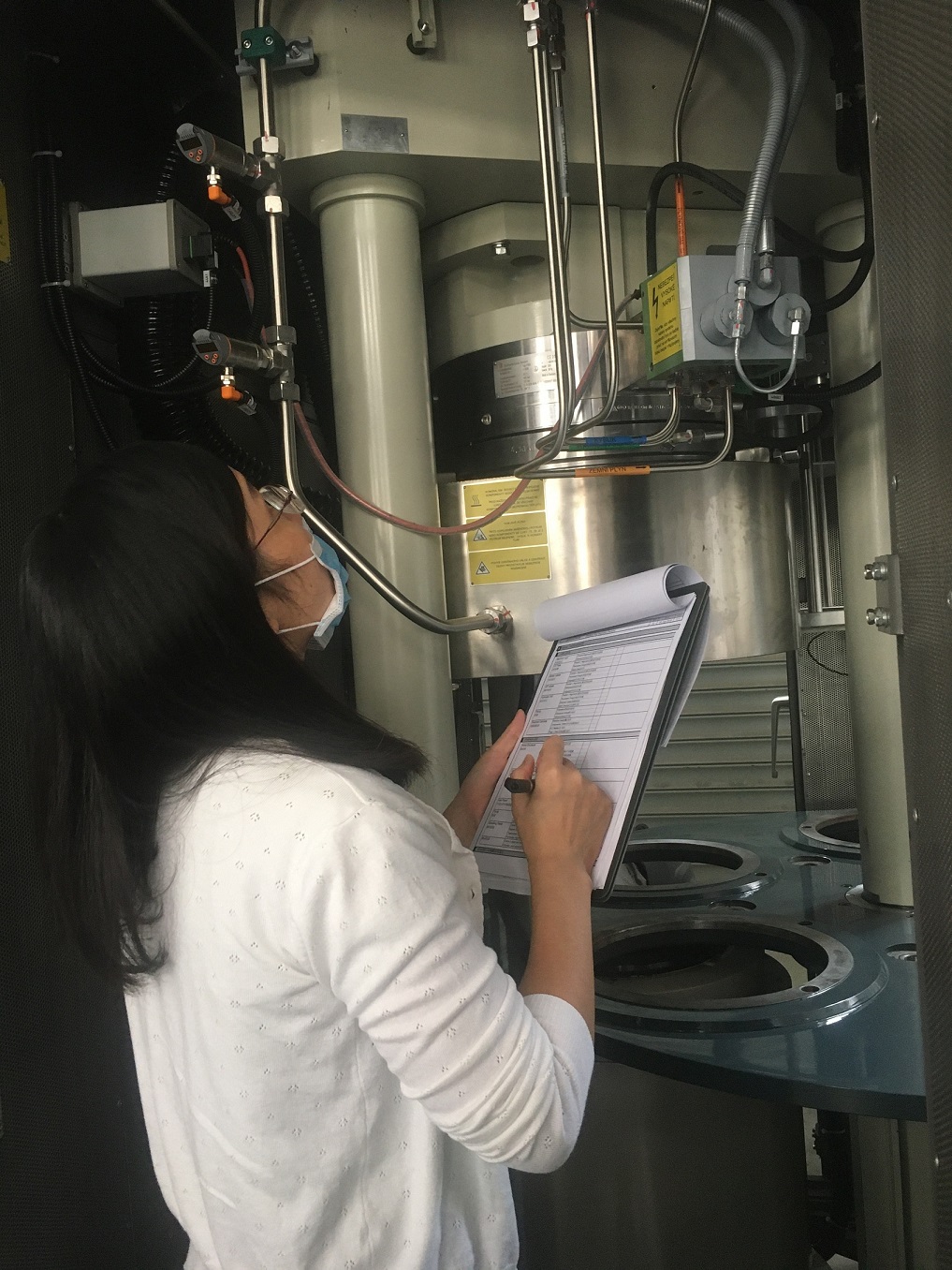

At Extrude Hone, we produce new machines and refurbish old ones.

Our business is not a throw-away goods business. Most of our machines are decades in the field, so we stand beside you to ensure they keep going with the highest standards.

As the uncertainty grows, the economy becomes more challenging and the budget tighter, do not give up making progress and get the best for less.

If you are not willing to invest in new equipment but like to move on with some projects then call us to discuss refurbishment.

We do refurbishment not only for Electrochemical Machining (ECM), but for Thermal Deburring (TEM) and Abrasive Flow Machining (AFM).

A special note for Thermal Deburring customers, facing the risk of a gas shortage, you can benefit from a kit to switch your machine to run on hydrogen.

One last thing. We would like to remind you about another proposition. We offer contract-shop services in many locations around the world offering another alternative to capital investment.